The Green ∫⁄∂¥…Á«¯ Store is building its Passivhaus home with cavity walls - not the usual choice but one that works at Denby Dale

As far as we know, the Denby Dale house will be the first Passivhaus in the UK built using cavity wall construction. European construction is typically solid masonry with external insulation and render or timber frame, and so Passivhaus buildings tend to use one of these two methods. But there are many ways of crossing a river, and we've decided to use cavity wall at Denby Dale, for three main reasons.

First, cavity walls contribute to a high thermal mass within the insulated building envelope – allowing a more even living environment, in terms of both acoustics and temperature. Through use of concrete blocks and concrete ground-floor slab within the thermal envelope, the house will have a greater thermal mass, which will act as a heat store, storing heat gained from passive solar gains.

Second, cavity wall construction is the method that we at Green ∫⁄∂¥…Á«¯ Company are most familiar with (we used it to build the Longwood low-energy house in the 1990s). We wanted to build a Passivhaus using British construction techniques, with, as far as possible, materials you could find in any local builder's yard.

Third, West Yorkshire planning rules require natural stone facing on the exterior of new buildings and so ruled out the option of block-built construction with rendered finishes.

The potential downside of cavity wall construction is that it relies on wet plaster to be the airtightness barrier on walls and junctions with doors, windows, floors and roof, whereas timber frame construction can be lined with vapour barriers and airtightness tapes etc, so our cavity wall Passivhaus will demand greater attention to airtightness detail.

This week I've been finalising choices for some materials on the build. We need to keep space heating needs at or below the magic figure of 15kWh/m2/annum – the prerequisite for Passivhaus certification. Modelling different materials in the Passivhaus planning package (PHPP) can have dramatic effects on that figure, and this week the figure has ranged between 19-14kWh/m2/annum, depending on which type of wall insulation and window configurations we have inputted.

I've been looking at options for mineral wool batts for the cavity wall – with options ranging from 100mm batts with lambda values of 0.037 (at a price of £2.68/m2) to 0.032 (£6.13 m2). We will be using 100mm batts three deep, which means tripling the price and, with 190m2 of walling, potentially we've got a £2,000 price difference between the different mineral wool options.

PHPP helps us to weigh up the cost implications of decisions with performance and allows us to play off one element against another. With PHPP you can decide on which bits of the elements you are going to compromise on and which bits you're going to upgrade in terms of thermal performance. In this instance, we've had to trade the need to accommodate more glazing on the north side of the building against having more expensive wall insulation. The Tunstalls' garden will be on the north side of the house and naturally enough they want to have sizeable windows on the north side to look at it. To give us flexibility in the sizing of the north-facing windows, we've decided to go for the more expensive batts with the lambda value of 0.032. The better insulation I can get in the wall cavity, the more view the Tunstalls will have of their garden.

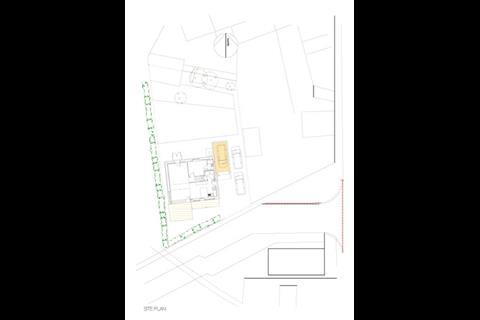

We have been delayed this week with the excavation work. At the last moment there was a change of mind regarding the position of the house – it is only a matter of one or two metres – but the local planning department have requested that we get statements from all the neighbours saying the new position is okay. Excavation work will hopefully start on Monday. Ralph the driver is breaking off from silage-making and coming over with his JCB and will get stuck in. Let's hope there aren't any more delays!

Oh, and in response to some requests from readers, I've also added a rough overall breakdown of costs on the build.

To visit the Green ∫⁄∂¥…Á«¯ Store, go to .

Postscript

Bill Butcher is director of the Green ∫⁄∂¥…Á«¯ Store

9 Readers' comments