Could Dessau’s latest office building set a new energy standard with its innovative use of geothermal heat exchange and solar air conditioning? Words and pictures by Crispin Matson

Back in the summer, I came across a very interesting building in Dessau, Germany – a town approximately one hour’s drive south of Berlin. What, in particular, caught my eye about this project (which turned out to be the Federal Environment Agency’s new headquarters) was the anticipated energy consumption target: only 30 kWh/m2. This sounded almost too good to be true, especially for an office building.

Having discovered the building in an architectural magazine (Architectural Review), there was scant detail on the engineering systems involved, but one visit to the architect’s website and a book purchase later, I had a little more detail on the design. Finally, in October,

I had an opportunity to visit the building en route to a conference in north Bavaria and the Agency gave me a guided tour.

On entering the building, my main impression was of a blaze of colour, which fluctuates as you walk around. Reds, oranges and yellows are used on the elevation facing Dessau, while blues and greens feature on the facade facing south towards the countryside. The use of timber inside gives a warm feel to the space.

How it all started

The brief was to provide a new building in Dessau with a net floor area of 25,375 m2 for up to 1200 staff relocated from Berlin. This was to include office space plus an auditorium, cafeteria, library, exhibition and information centre. A competition held in 1997 was won by Sauerbruch Hutton Architects, a German/ English practice. Construction of the new building started in 2002 and was finished in summer 2005, with a total budget of £45m. But what made this a real challenge for the designers was that, not only did the building have to be sustainable, its energy performance was to be at least 50% better than required by the energy conservation laws in force at the time.

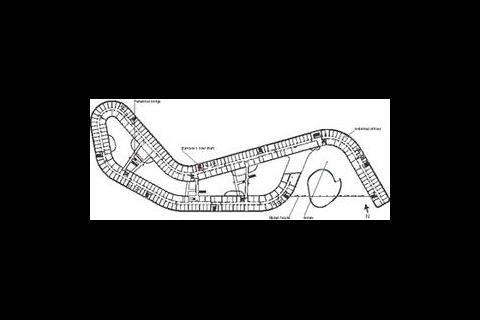

On visiting the building, some of the features that contribute to its predicted low energy consumption are obvious. To begin with, the building has been designed to minimise the area of external facade. With individual 12 m2 offices required for each member of staff, each with an outside window for ventilation and natural daylight, you might expect the result to be a long narrow floor plate of offices either side of a central corridor. Instead, the architect has taken this “snake” and turned it on itself to create a relatively compact form, with an atrium space spanning the offices.

Using this solution, approximately 30% of the offices face on to the internal atrium, with a correspondingly reduced heat loss. Heat loss for those offices with an external facade has been minimised through high levels of thermal insulation for the fabric. External windows are triple glazed with a U value of 1.2 W/m2K. The external wall is constructed of prefabricated timber (at 1 km long, it’s the longest in the world) and has a U value 0.23 W/m2K. The roof has been constructed as a green roof with a U value of 0.13 W/m2K.

Ventilation

Energy consumption is further limited by maximising natural ventilation. Every office is approximately 5 m deep and has a large tilt-and-turn opening window to the external facade or the atrium. To avoid overheating in the summer, retractable horizontal blinds sandwiched within the triple-glazed window, provide adjustable solar shading. In the atrium, similarly, mechanically operated roller blinds provide additional shading to the glazed roof.

In addition to the natural ventilation system, the building has an energy efficient mechanical ventilation system. Supply air is drawn through an underground geothermal heat exchanger by four air-handling units in the basement.

The heat exchangers are used throughout summer and winter. Over 5 km of subterranean ducts provide an annual output of 86,000 kWh of heating energy in the winter and 125,000 kWh of cooling energy in the summer. The network of underground pipes includes 1500 mm diameter concrete header ducts and smaller 300 mm diameter metal cross ducts. The five air intakes are sculptures made out of folded steel, located around the external perimeter.

138,000 m3/h (38.33 m3/s) of air is introduced through the four air-handling units, via riser shafts located beside the staircase cores into the offices and the base of the atrium.

The exterior and interior offices are independently controlled. From the riser, air is mechanically ducted and supplied to each office via a narrow linear slot diffuser located in a bulkhead above the door. Air is exhausted from to the corridor via special sound-absorbing slots located in panels beside the doors. The corridors act as a return air plenum.

In the winter, air is extracted directly from the corridors into the exhaust air duct at five places on every floor next to the main risers, where it is passed through a heat exchanger before being expelled. In the summer, the exhaust air travels directly into the atrium through natural convection. Heat recovery is fitted to all air handling units.

Apart from specialist areas (see below), there is no mechanical cooling. Instead, the heavy thermal mass of the building has been used, with ventilation, to cool the structure at night. This is achieved by large mechanically operated opening vents in the glazed atrium roof, in combination with mechanically operated openings adjacent to, and independent from, each external window. These openings allow night air to enter the perimeter rooms via external louvres – secure and protected from the rain. The atrium also has additional vents at ground floor level which can be used in high temperatures to flush through this space.

Sunlight provides cooling

A solar air conditioning system provides cooling for the conference room and the kitchen’s walk-in freezers. 354 m2 of solar vacuum tube heat collectors at roof level provide a peak thermal output of 242 kW. These feed a 69 kW cooling capacity adsorption chiller, which uses silica gel. Additional heat for the chiller is supplied from a district heating system.

The energy source for the district heating plant (Stadtwerke Dessau) is a local landfill gas site, which provides 906 kW to the building. The heat is used in the ventilation plant for background heating, hot water and to drive the adsorption chiller. The solar water panels supplement the heating system. Each office has its own individually controlled radiator designed to achieve a room temperature of 228C.

Additional renewables have been provided in the form of photovoltaic cells integrated into the atrium glazed roof: 228 m2 of cells achieve a peak electrical output of 31.3 kW and an annual output of 24,000 kWh.

Energy consumption for the lighting has been minimised partly by optimising the use of daylighting and partly by using a lighting control system. The relatively narrow width of the office floor plate ( 11.8 m) ensures good daylight penetration. In addition, the proportion of window glazing has been optimised throughout 35% of the exterior and 60% of the interior facades to maximise daylight without too much solar gain. Finally, internal surfaces direct and reflect daylight. Lighting control to individual offices is achieved by an occupancy control system.

Overall impressions

The building is well appreciated and appears busy. I was able to go into the individual offices, play around with the opening windows and was also given an impressive demonstration on their electrically operated moving work tables which can be lowered or raised to suit each individual’s preferences.

A few minor faults were observable, including noisy air plant noticeable on the town side of the building, timber cladding warping within the atrium and no water in the atrium water feature due to concerns regarding the water treatment.

I was, however, lucky enough to visit on a gloriously sunny autumn day and overall, the building looked truly spectacular. Later, speaking to Louisa Hutton at the architects’ office, she said how much people were impressed, not only with the energy credentials of the scheme, but also the modest budget. The total building cost works out at £1.16 /m2.

Some of the technologies used in this building are not particularly new. Natural ventilation, coupled with night cooling to an exposed concrete mass, is an effective low-energy comfort cooling system where close temperature control is not expected. What makes this building different is the coupling of these well-proven techniques with the geothermal heat exchanger and the solar air conditioning.

It is claimed that the geothermal heat exchanger is the world’s largest. To my knowledge, their previous application in Germany and the UK has been on relatively small scale cultural projects – certainly not major office buildings. The big question is its cost and how effective it is compared with, say, a water-based ground coupling system. Without more detailed costing it is difficult to know.

Solar air conditioning is also a new concept. Germany has been at the forefront of its application, with a number of research institutes experimenting with pilot plants. The individual components are well tested, but their successful application is still relatively new. Again, I am not aware of any previous application in such a large scale office project in Germany or the UK.

The building is currently being monitored and it will be interesting to see the results of these new technologies, when they are published in 2007. If the building does achieve an energy consumption of only 62 kWh/m2, it will be operating over five times more efficiently than London’s GLA building, which was recently reported as having an energy consumption of 367 kWh/m2. It will set a new standard for office buildings: a true low energy office.

Source

�ڶ����� Sustainable Design

Postscript

Crispin Matson is managing director of Rybka.