When the Natural History Museum decided it needed to house 20 million insect and plant specimens within one structure, building a giant shiny, ivory coloured cocoon seemed to make perfect sense. Thomas Lane buzzed over to find out more ŌĆ”

If a cocoon is the perfect place for a pupa to grow before emerging as an adult insect, wouldnŌĆÖt it also be a good place to protect its body from harm once dead? The reasoning may seem strange, but the Natural History Museum has seized this logic and used it as the way to stop its collection of insect and plant specimens from deteriorating. Hence the cocoon-shaped storage facility that it is building at its west London site, which will also include space for scientists to work and areas for the public. ŌĆ£One of our remits is to safeguard those specimens for the nation,ŌĆØ says Neil Greenwood, who is the Natural History MuseumŌĆÖs project director. ŌĆ£Previously these were not stored in the best conditions. The cocoon will provide an ideal storage facility.ŌĆØ

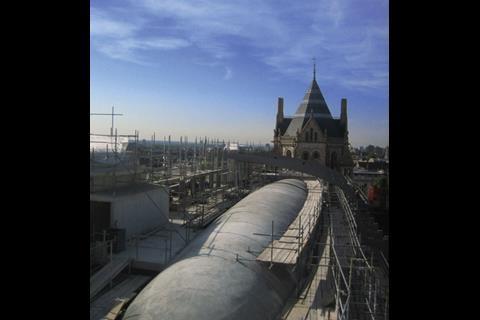

When you have 20 million specimens that need 3.3km of cabinets to house them, you need a very, very big cocoon. This one is 65m long, 12m wide and eight storeys high, and fills most of the rectangular building being constructed around it, the ┬Ż75m Darwin Centre 2. Ed Newman-Sanders of Arup, the structural engineer on the project, likens the view from above of the enormous structure as ŌĆ£a submarine emerging from the waterŌĆØ.

The design team has treated the cocoon concept as literally as possible. Specifically, it is a silk bubble, with a series of what appear to be threads crisscrossing its surface. The overall effect is quite beautiful, ivory coloured with a subtle sheen. And as it emulates a natural object, it does not have a regular shape. ŌĆ£The cocoon is totally freeform, and is very difficult to define mathematically,ŌĆØ says Newman-Sanders. This, coupled with the fact that the cocoon was actually a structural component, meant it was not easy to build, but the design team and contractor HBG have pulled it off with the help of some very specialist contractors. How did they get on?

Rhino, the 3D modelling program, was the key to creating the form of the cocoon and enabling the contractors to build it.

CF M├Ėller, the Danish architect that created the shape, did so using the program, then Arup used it to define the structure before passing the model over to HBG and its specialist contractors.

But how did they take this virtual model and turn it into something real? The challenge was complicated by Arup wanting to maximise the space inside the cocoon. It wanted to eliminate the internal columns the walls as a structural element, even though the samples within were very heavy and the load on the floors was about three times that of an office building.

Four structural options were considered: steel frame, precast concrete, insitu reinforced concrete and sprayed concrete. Steel frame was quickly discounted because it would have provided hiding places for the dreaded museum beetle to breed. (This is not a joke: anthrenus museorum can rapidly destroy entire collections, so the whole building has been designed without hidden nooks and crannies.) Precast was discounted as too expensive and the complex shuttering needed for reinforced concrete would have made the structure painfully slow to build.

That left sprayed concrete as the favourite because, according to Alan Grant, HBGŌĆÖs construction manager, ŌĆ£you get the right shape the first timeŌĆØ. It was also cost-effective and quick. But it had one disadvantage over reinforced concrete: the building surrounding the cocoon and the floor slabs inside it had a conventional reinforced concrete structure. If the cocoon had also been built using reinforced concrete, it would have been relatively simple for one specialist contractor to build them together. Sprayed concrete, however, is a very different process and is done by a separate specialist.

Grant says integrating the two operations was a big challenge because the mess created by the sprayed concrete would not have gone down well with the reinforced concrete specialist. ŌĆ£The downside of sprayed concrete is itŌĆÖs a messy operation,ŌĆØ says Grant. Our concern was you couldnŌĆÖt bring the reinforced concrete frame up with the sprayed concrete. We would have ended up with a mutiny.ŌĆØ

The answer was to build the reinforced concrete frame first, then the cocoon, but this created the problem of how to support the slabs next to the cocoon before its construction.

Temporary steel works turned out to be very expensive, so the reinforced concrete frame contractor Getjar proposed incorporating full-sized columns to support the slabs, then removing these afterwards. This turned out to be the cheapest solution, so 13 columns supporting the slab edges were duly incorporated into the structure ready for work to start on the cocoon.

║┌Č┤╔ńŪ° the cocoon structure

The ┬Ż1.6m cocoon structure was built by sprayed concrete specialist Shotcrete, and according to its managing director Stuart Manning is now the first above-ground sprayed concrete structural element in the world. This is particularly impressive when you consider that all he had to help him build it was a computer model. ŌĆ£We were provided with the Rhino model and told that this was what we had to build,ŌĆØ he says. He also given a series of flat, reinforced concrete slabs with the rebar sticking out ready for incorporation into the cocoon.

Shotcrete worked with Arup from an early stage in the project to determine how to approach it. The first stage was to erect scaffolding between the slabs with a series of poles sticking horizontally out into the space where the cocoon was going to be built. Using the Rhino model, a surveyor marked on the scaffolding where the reinforcement on the inner and outer side of the wall should be placed. ArupŌĆÖs Newman-Sanders says they came up with the idea of using straight rather than pre-bent rebar for the reinforcement cage. Arup specified the size of the rebar and the spacing between fixing points; the idea was the rebar would naturally bend to form the correct shape.

Horizontal bands of rebar were placed first followed by the vertical bands. ŌĆ£That gave us a reinforcement mat that was curving exactly to the shape of the structure,ŌĆØ says Manning. He says forming the apertures in the walls of the cocoon to allow access for scientists and the public wasnŌĆÖt easy. ŌĆ£The openings were most demanding,ŌĆØ he says. ŌĆ£Every opening was irregular in shape, the heads were crooked, the sides werenŌĆÖt straight and the whole thing is curved.ŌĆØ The only way to form the apertures was to place the concrete first, then cut the rebar away afterwards. Leaving gaps for the apertures would have meant the cocoon would have lost its flowing shape.

With the rebar in place, expanded mesh was fitted to the inside face of the rebar and a 200mm thick layer of concrete sprayed on. Then a 35mm thick finishing coat was sprayed on to either side of the bulk concrete and smoothed off, ready for the next stage in the cocoonŌĆÖs evolution.

The finishing touches

The next stage was to turn 3,500 square metres of raw concrete surface into something that resembled a giant silk cocoon. This was done using an ivory-coloured polished plaster finish, in which a series of channels resembling silk threads wrapping around the cocoon were incorporated. The outer surface of the cocoon was insulated to shield the interior as much as possible from external temperature variations. Because this outer layer is exposed to the sun coming through the glass facade on one side, movement of this skin was a worry. Grant says these issues were new to HBG and it wanted to minimise its risk, but the trouble was that polished plaster companies tend to be very small. ŌĆ£From our point of view we wanted a single point of responsibility by letting the insulation and polished plaster as a package,ŌĆØ he says. ŌĆ£We interviewed about four companies and most were very keen to do the polished plaster bit but not the insulation or setting out. Plus they couldnŌĆÖt say whether the stuff would drop off.ŌĆØ

Only one company ŌĆō Armourcoat ŌĆō was prepared to take the job on as a package. Although it has done bigger contracts than this ┬Ż1m job, this one was particularly challenging. ŌĆ£It was unique because of its complexity and because we were working from first principles,ŌĆØ explains Duncan MacKellar, the firmŌĆÖs creative director.

The first job was to attach a 50mm thick layer of polystyrene to the concrete and coat this with a layer of reinforcing mesh embedded in resin to give a firm surface to work on. Then the surface was surveyed and marked out ready for the crisscrossing ŌĆ£threadsŌĆØ. These are actually channels cut into the insulating layer, which Armourcoat creating by fixing a series of metal tubes temporarily to the cocoon surface where the threads would be located and using a special cutting tool to make the grooves. ŌĆ£We got an engineers workshop to make us a twin-wheeled cutter with four roller blade wheels that would fit over the steel bar so it acted as a guide,ŌĆØ explains MacKellar.

Once the channels were cut, an edge bead was fitted to the sides of the grooves, then a silver-coloured plastic strip, which sits 10mm below the finished surface, was clipped in place. ŌĆ£We had to fit 5.6km of edge bead. The setting out of the bead was one of the hardest parts of the project for us, as it had to be perfect at the interfaces which were very hard to set up accurately,ŌĆØ says MacKellar.

The threads slice the surface of the cocoon up into a series of panels which vary in size from 50m2 down to fractions of a square metre. These can expand and contract with the movement taken up by the gaps between the panels. Each panel was coated up with an anti-crack coating ruled off by hand with lengths of plastic-coated MDF to give a perfect surface. Then the standard Armourcoat basecoats were applied followed by the ivory-coloured plaster finishing coat.

The end result is impressive. Anna Maria Indrio, project architect CF M├Ėller, wanted the cocoon to look as natural as possible. ŌĆ£It should have a materiality that shows it is a handmade thing,ŌĆØ she says. And it does. The overall shape is very naturalistic, the surface is gently irregular and the texture of the plaster finish subtly varies across the surface. It will not only undoubtedly protect the museumŌĆÖs valuable specimens but will attract new visitors to the Natural History Museum, like moths to a flame.

What the building is for and how it works

ŌĆ£It isnŌĆÖt just a dinosaur museum for children,ŌĆØ explains the Natural History MuseumŌĆÖs Neil Greenwood. He says the museum is also an internationally important centre for reference and research. The new Darwin Centre 2 has three main functions: to store and preserve the museumŌĆÖs 17 million-strong insect collection and three million plant specimens, provide new facilities for scientists working in the museum, and enable the public to see this part of the museum in action.

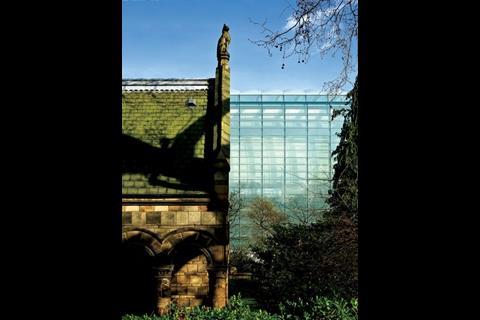

The building is rectangular, with three sides attached to existing Natural History Museum estate. The fourth side faces QueenŌĆÖs Gate and is glazed so the full length of the cocoon is visible to people in the street. This area doubles up as a full height atrium and acts as a buffer zone between the cocoon and the outside, as the atrium is unheated except at low level where the public will circulate.

In the north end of the Darwin Centre is a block that will house facilities for scientists and the other end contains an administration block. It also contains lifts that will take the public up to the eighth floor so they can walk along a series of sloping ramps inside the cocoon then out again so they can see the scientists at work.

The cocoon performs a genuinely protective job. It is externally insulated, and its exposed concrete structure and the exposed slabs and columns provide plenty of thermal mass which will help regulate its internal temperature. ŌĆ£If all the plant was turned off it would take days for the temperature to change inside the cocoon,ŌĆØ says Peter Nissen, the director at Fulcrum Consulting, M&E consultant on the project. The temperature is maintained inside the cocoon at a steady 17┬░C, which is too cold for museum beetles to breed. The air is kept at a constant 45% relative humidity, which helps preserve the collection. Nissen says the low level of humidity is potentially energy hungry, but energy use is minimised by using the museums central CHP plant to dry the air. Centralised plant also supplies chilled water to the air handling units.

All the services are exposed, not because it is trendy, but because it makes these easier to clean and keep beetles under control. Background air is supplied by large air handling units in the basement. Fulcrum was concerned about pockets of warm air forming, owing to uneven air movement, so two local air handling units were installed on each floor to help with even air flow. These can also take care of any temperature fluctuations, for example, those caused by people.

Procurement

Contractor HBG was given the ┬Ż44m contract to build Darwin Centre 2 in August 2005. The project is worth ┬Ż75m overall and was procured using an NEC3 contract. This promotes collaborative working, as there is a target price, but the client and contractor share the pain if the sum is exceeded or gain if it is under budget. Despite the unusual nature of the project the Natural History MuseumŌĆÖs Neil Greenwood didnŌĆÖt feel it was too risky for this form of contract. ŌĆ£The structure may be unique in shape but in construction terms there are other similar structures so we didnŌĆÖt feel it was too risky,ŌĆØ he says.

HBGŌĆÖs Alan Grant says he likes the NEC contract, as variations arenŌĆÖt left to the end to sort out. ŌĆ£As change occurs it is dealt with at the time,ŌĆØ he says. The collaborative approach is clearly working as Grant says relations between teams are very good.

Work started in June 2006, with the piling package. The client had already engaged its own specialist to demolish the existing entomology building on the site.

The contract period is 110 weeks, with completion due in July. Grant says it is on schedule and budget, but it wonŌĆÖt open to the public until autumn 2009. This is to give the museum time to move 20 million specimen into the new building. ŌĆ£ItŌĆÖs a huge exercise and will be quite a challenge,ŌĆØ says Greenwood.

Client Natural History Museum

Architect FC M├Ėller Architects

Project manager Manly

Structural development Arup M&E Fulcrum Consulting QS Turner & Townsend

Main contractor HBG Construction

Structural concrete Shotcrete Services

Groundworks McGee Group

Piling Westpile

Reinforced concrete frame Getjar

Structural steel Watson Steel Structures

Scaffolding Brogan Scaffolding

Roof Covertex Management Systems

Curtain walling Permasteelisa M&E

Installation Meica Services

Polished plaster and insulated render Armourcoat

Downloads

Site plan

Other, Size 0 kb

No comments yet