When Ramboll was faced with the problem of designing a lightweight, long-span floor capable of withstanding the combined weight of a school dance class, it needed to come up with some exciting new moves ŌĆ” ║┌Č┤╔ńŪ° reports

When Plato coined the phrase ŌĆ£necessity is the mother of inventionŌĆØ, he wasnŌĆÖt thinking about designing long-span floors suitable for dance studios with limited headroom. But engineer Ramboll was faced with this challenge and has come up with a new form of floor construction born out of a long list of constraints. Its innovation has good acoustic, fire and thermal properties, and is very green too.

Ramboll was working with architect Make and contractor Kier on the redevelopment of Thomas Clarkson Community College in Wisbech, Cambridgeshire. Most of the buildings on the campus are relatively straightforward, being constructed with steel frames and hollowcore plank flooring.

But one three-storey block had to house a dance studio and very large classrooms above, which needed floors that could span 10m. The block is connected to an existing building so the floor-to-ceiling heights were already determined. Furthermore, the poor Fenland ground favoured a lightweight structural solution. ŌĆ£The ground had very low capacity - we joked it had more in common with custard,ŌĆØ laughs Oliver Neve, RambollŌĆÖs structural engineer, who led this project.

Because dancers leap around, the dance studio needed a floor-to-ceiling height of 3.2m, which meant the floor slab couldnŌĆÖt be more than 420mm deep. It was also subject to stringent vibration criteria - the floor needed to be stiff enough not to deflect when the combined weight of a troupe of dancers jumped up and down on it at the same time.

A floor supported by steel beams would take up too much space. A post-tensioned concrete floor had the advantage of being relatively shallow but was ruled out because it would have needed to be combined with a concrete frame, which would have added too much weight to the foundations.

The solution

Neve favoured constructing the building structure out of cross-laminated timber (CLT), as this is lightweight, fast to construct and locks carbon in the timber, giving it a very low environmental impact. CLT buildings usually have floors made from the same material, as a 300mm-deep slab is sufficiently stiff to span up to 7.5m, which is fine for most applications. For this longer span, Neve decided that a composite timber floor could be the answer.

A composite floor is a combination of a material good at resisting tensile loads and one that can resist compressive loads. Many steel-framed buildings have composite floors, consisting of steel beams supporting a crinkly tin metal deck, onto which a concrete topping is poured. The steel takes the tensile loads and the concrete the compressive loads.

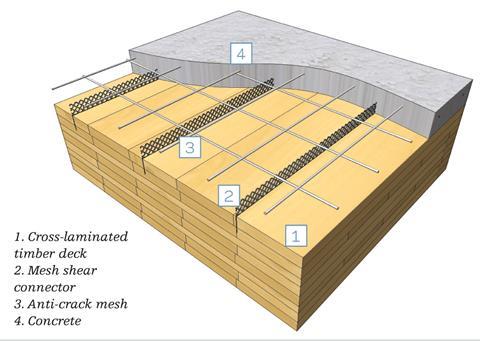

For this project, the addition of a 100mm layer of concrete would increase the stiffness of the CLT floor slab by three-and-a-half times, making it sufficiently strong for the dance studio and the classrooms above, while keeping within the headroom constraints.

Using CLT for both the structure and the floor had the added advantage of speeding up construction.ŌĆØThe real advantage is that we are using one supplier who can do the whole thing,ŌĆØ explains Neve. ŌĆ£The only other work is pouring the concrete, which is something the contractor can do really easily.ŌĆØ

Connecting the slab

The concrete and timber need to be securely linked together by a shear connector to work as a composite structure. Composite timber floors arenŌĆÖt new - in the Second World War, when steel was in very short supply, wooden planks were used, with partially driven screws as the connectors with the concrete. But this job is the first time CLT has been used as a composite and Neve wanted to come up with a better shear connector than screws, as this would mean the floor would be stiffer.

The answer was to use regularly spaced strips of steel mesh perpendicular to the CLT. Slots are cut into the CLT, the mesh inserted and fixed into place with resin. This was done in the Austrian supplierŌĆÖs factory, ready for the concrete pour once the panels had been fixed into position.

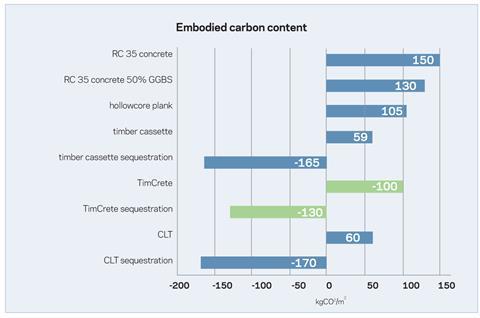

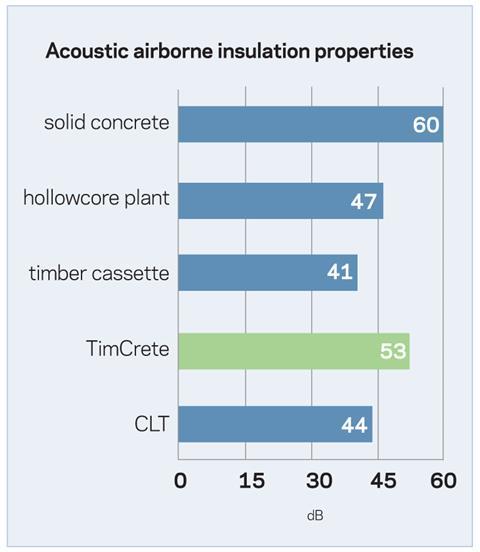

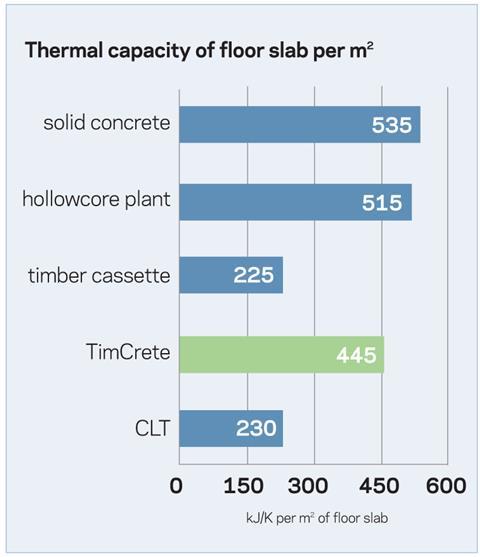

Neve says post construction tests show the floor is performing slightly better than predicted by computer modelling. It also has better acoustic and fire performance than a plain CLT slab and has more thermal capacity, which will help to regulate internal temperatures. A composite timber floor is carbon-negative even when the concrete is accounted for.

The only downside to the composite CLT floor is that it is more expensive, but Neve says that there are programme savings which havenŌĆÖt been quantified on this job. Ramboll has high hopes for this solution and has named it TimCrete in anticipation of seeing the system used more widely.

How the floor performs

How the floor fits together

No comments yet